[Go back to Part 2…]

I had a plan for how to blog about this project, but I’m going to step out of order and talk about the latest development since it pertains to the last Fusion 360 Meetup. So to catch up in a hurry: I’ve already constructed a control box containing an Arduino Mega 2560 and a Raspberry Pi, power supplies, relays, etc. all mounted on DIN rails. This is the “brains” of the system, and the Pi runs an open source control framework called EPICS. The control box sits on a separate stand on wheels that I welded. In keeping with the “Beer Church” theme, I suppose this is the “Beer Pulpit”.

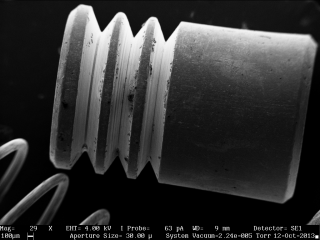

I realized early on that the control box was out of room. I want this brewing system to be modular so that I can attach different equipment and reconfigure everything via software. To that end, each device needs to connect to the control box with its own sturdy, detachable connector. The original BrewTroller project (which isn’t online anymore) made use of XLR jacks. These are ideal. Nearly every device I’m interfacing with uses 3 or, in some cases, 2 wires. The OneWire serial bus, which is used for measuring temperatures, uses a 3 pin M12 connector; these are chained together using splitters. A few use cases need more than 3 wires: multiple pressure transducers on one board (used for fluid level sensors) and stepper motor drivers (used for controlling gas needle valves). For these, I’m using 8 pin mic connectors. But I don’t have enough panel space on the control box for all of these jacks, especially now that I’m considering adding a small touch screen. Nor do I have room inside the control box to mount a 120 V to 24 V transformer; 24 VAC is a HVAC standard, and the propane burner valves need it.